Views: 2 Author: Site Editor Publish Time: 2024-05-09 Origin: Site

Rivets play a pivotal role in sheet metal assemblies, offering robust connections, structural integrity, and enhanced quality in a wide range of applications across industries. This technical article delves into the intricacies of using rivets in sheet metal fabrication, highlighting their significance in improving part connections and overall assembly quality.

The Power of Rivets in Sheet Metal Applications

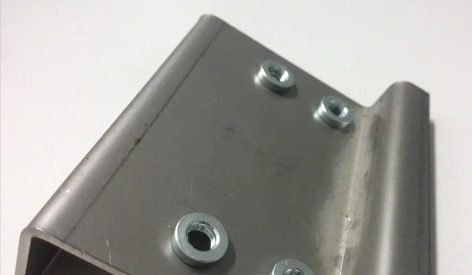

Secure Connections: Rivets provide secure connections between sheet metal components, ensuring stability, strength, and durability in assembled structures. Their ability to withstand mechanical stresses, vibrations, and dynamic loads makes them indispensable in applications where reliability and safety are paramount.

Enhanced Structural Integrity: By distributing loads evenly across joint interfaces, rivets enhance the structural integrity of sheet metal assemblies, minimizing stress concentrations and preventing premature failure. This results in assemblies that can withstand harsh operating conditions, environmental factors, and mechanical forces with confidence.

Improved Assembly Efficiency: Riveting offers a streamlined assembly process, allowing for quick, efficient, and cost-effective joining of sheet metal parts. Compared to welding or adhesives, riveting requires minimal preparation, reduces heat-affected zones, and eliminates the need for additional curing or cooling times, leading to accelerated production timelines and improved efficiency.

Key Advantages of Riveted Sheet Metal Assemblies

Versatile Joint Designs: Rivets enable a variety of joint designs, including lap joints, butt joints, T-joints, and corner joints, providing flexibility in assembly configurations and geometries. This versatility allows engineers to optimize designs for specific load requirements, space constraints, and aesthetic considerations.

Corrosion Resistance: Utilizing corrosion-resistant rivets, such as aluminum, stainless steel, or coated rivets, enhances the longevity and performance of sheet metal assemblies, particularly in outdoor, marine, or corrosive environments. Proper material selection and surface treatments mitigate corrosion risks, preserving the appearance and functionality of assembled structures over time.

Aesthetic Appeal: In addition to their functional benefits, rivets contribute to the aesthetic appeal of sheet metal assemblies, lending a professional finish, uniformity, and visual appeal to finished products. Strategic placement of rivets can enhance design aesthetics while maintaining structural integrity and performance standards.

Optimizing Riveting Processes for Quality Results

Precision Rivet Selection: Choosing the right rivet type, size, material, and head style is crucial for achieving optimal joint strength, load-bearing capacity, and overall assembly quality. Conducting thorough engineering analyses and testing ensures compatibility with sheet metal thicknesses, hole diameters, and assembly requirements.

Proper Installation Techniques: Employing proper rivet installation techniques, such as pneumatic, hydraulic, or manual riveting methods, ensures consistent, reliable, and high-quality joints. Attention to detail, including rivet spacing, hole preparation, rivet setting force, and inspection procedures, minimizes installation errors and maximizes joint performance.

Quality Assurance Protocols: Implementing stringent quality assurance protocols, such as dimensional checks, rivet pull-out tests, joint strength evaluations, and visual inspections, verifies the integrity and functionality of riveted sheet metal assemblies. Continuous monitoring, feedback loops, and process improvements uphold quality standards and customer satisfaction.

Conclusion: Strengthening Sheet Metal Assemblies with Riveting Expertise

Rivets stand as a cornerstone of excellence in sheet metal fabrication, offering unmatched strength, reliability, and aesthetic appeal in assembly solutions. By harnessing the power of rivets, optimizing installation processes, and prioritizing quality assurance measures, manufacturers can elevate the performance, durability, and value of sheet metal assemblies across diverse applications and industries.

Are you looking for sheet metal rivet technology? jucheng Precision can provide complete sheet metal fabrication services

Discover the pinnacle of sheet metal rivet with Jucheng Precision's sophisticated sheet metal rivet technology. Our cutting-edge techniques ensure precision down to the smallest detail, delivering unmatched quality and durability. Whether you need custom-designed sheet metal nails or intricate metalwork solutions, our expertise and state-of-the-art equipment guarantee flawless results. Trust Jucheng Precision for excellence in sheet metal fabrication, tailored to meet your unique requirements and exceed your expectations.