Views: 3 Author: Site Editor Publish Time: 2024-05-06 Origin: Site

In the realm of metalworking, turning stainless steel stands out as a critical process, blending precision, durability, and aesthetic appeal. This article delves into the intricate balance of cost control and quality assurance within stainless steel turning, navigating through techniques, challenges, and future outlooks.

Introduction: Unveiling the Essence of Stainless Steel Turning

Stainless steel's ubiquity in industries spanning automotive, aerospace, medical, and beyond underscores its indispensable role. However, achieving the delicate equilibrium between cost-effectiveness and impeccable quality is where the art and science of turning stainless steel truly shine.

Historical Evolution: From Craftsmanship to Precision Machining

Tracing back, stainless steel turning has traversed a fascinating evolution. What once relied heavily on manual craftsmanship has metamorphosed into a realm dominated by CNC precision machining. This shift has not only enhanced productivity but also set new benchmarks in accuracy and repeatability.

Cost Control Strategies: Navigating the Financial Landscape

Controlling costs in stainless steel turning demands a multifaceted approach. It begins with judicious material selection, where understanding the nuances of various stainless steel grades and their machining characteristics is paramount. Tooling optimization, efficient machining strategies, and streamlined processes further bolster cost-efficiency without compromising on quality.

Quality Control Imperatives: Precision Redefined

Quality in stainless steel turning transcends mere dimensional accuracy. It encompasses surface finish, metallurgical integrity, and adherence to stringent specifications. Employing advanced metrology tools, rigorous inspection protocols, and continuous process monitoring are pivotal in upholding uncompromising quality standards.

Advanced Techniques: Pioneering Innovation in Turning

Embracing technological innovations like high-speed machining, multi-axis CNC capabilities, and adaptive machining algorithms propels stainless steel turning into realms of unprecedented efficiency and precision. These advancements not only optimize costs but also elevate the overall quality paradigm.

Challenges and Solutions: Overcoming the Hurdles

Navigating the intricacies of stainless steel turning isn't devoid of challenges. Tool wear, thermal effects, chip control, and surface finish intricacies often pose hurdles. However, proactive tool management, optimized cutting parameters, and strategic coolant usage serve as potent solutions to surmount these obstacles.

Applications Across Industries: Powering Diverse Sectors

The versatility of turned stainless steel components finds expression across a myriad of applications. From intricate aerospace components demanding utmost precision to robust automotive parts requiring durability and corrosion resistance, stainless steel turning's impact reverberates across diverse industrial landscapes.

Future Trends: Paving the Path Ahead

As technology continues to evolve, the future of stainless steel turning looks promising. Automation, data-driven analytics, and sustainable machining practices are poised to reshape the cost-quality dynamic, driving efficiencies and sustainability hand in hand.

In conclusion, mastering cost control and quality assurance in turning stainless steel isn't just about the process; it's about crafting excellence that transcends expectations, propelling industries forward with each precision-engineered component.

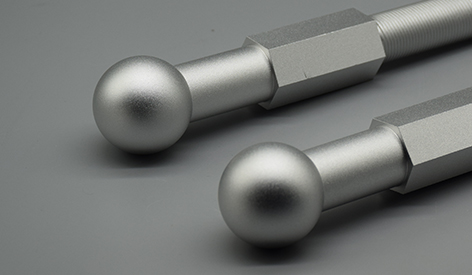

Learn more about Jucheng precision turning stainless steel customization capabilities

Jucheng Precision with its excellent technology and exquisite craft, to provide customers with excellent stainless steel turning processing services. Our state-of-the-art equipment and experienced team are dedicated to customizing high quality stainless steel parts for customers in all industries. No matter what industry you need custom stainless steel parts for, we can provide the best quality solutions. By choosing Jucheng Precision, you will have a reliable partner to provide professional, efficient and precise stainless steel turning services for your project.